Accurate data is the most crucial asset to work across all industries, including construction. Now that digital transformation is taking over the business landscape, the ability to capture and accurately analyze good data is quickly becoming even more vital.

Mixed reality (MR) is revolutionizing data capture and analysis in the construction industry, enabling companies to make more informed decisions, stick to project timelines and reduce unnecessary costs.

What Is Mixed Reality and How Does It Work?

To properly understand mixed reality, it helps to understand the concept of extended reality (XR). XR is an umbrella category referring to any digital technology that alters the user's perception of reality, such as:

- Virtual reality (VR): VR is a completely virtual experience, meaning that the user interacts with only virtual elements in a completely virtual environment. Many construction companies use VR simulations to safely train operators on new equipment or even immersively walk through a design before construction has even started.

- Augmented reality (AR): AR uses a screen and camera to place a digital overlay on the physical environment. For example, you could use a mobile app to view what a 3D model of a structure would look like on your job site before beginning construction.

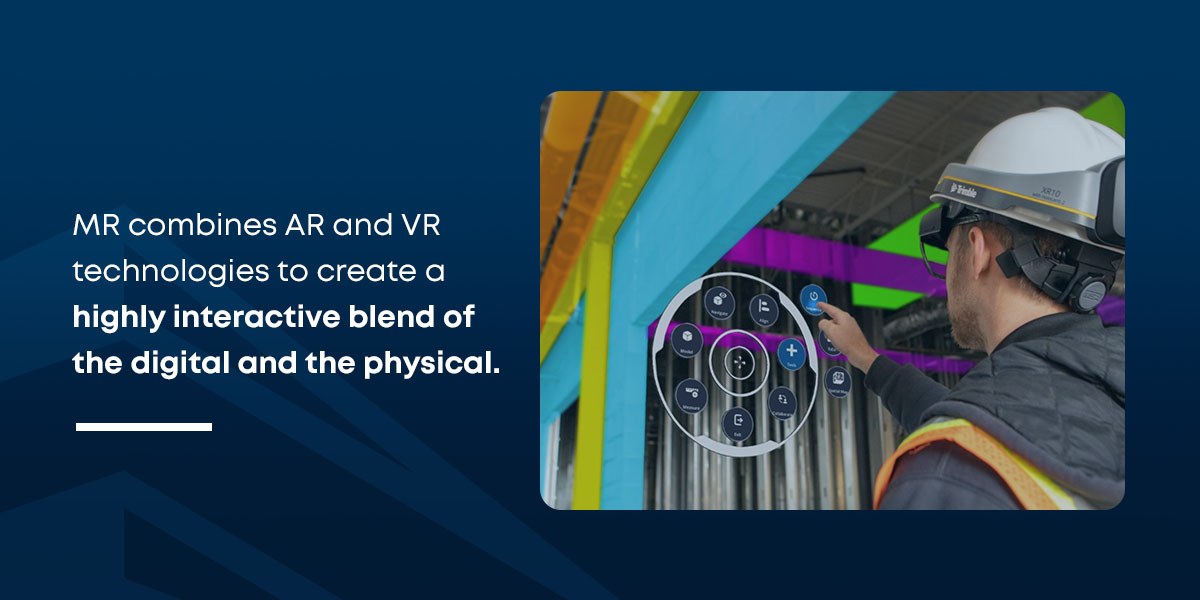

- Mixed reality (MR): MR combines AR and VR technologies to create a highly interactive blend of the digital and the physical. The experience uses a headset equipped with sensors to add interactive digital elements to the real world, allowing users to directly engage with everything in their sight.

The following components of mixed reality technology are what enable such a unique and revolutionary experience:

- Holographic Waveguides: This is what allows the user to see the holograms in front of them while also being able to see straight through the lenses. It works similar to how a projector would display an image on a screen except in this case the image is being projected onto plexiglass.

- Photogrammetric Mesh: A mix of sensing technology on the headset allows a real time capture of the environment that quickly converts physical elements to digital (otherwise known as a spatial map). Every step the user takes in the real world is a step taken in the alternative digital world as well.

- Spatial Anchors: To prevent the digital content from drifting as the user moves, they need a way to stay in place. This is where spatial anchors come into play to act as pins for the digital content in the real world environment. These usually come in the form of QR codes or other markers and act as control points in the MR experience.

Applications for Mixed Reality in Construction

Although MR is still a fairly new technology, it's been picking up steam in the industry for some time now. Some notable examples of how the construction industry is using MR include:

- Design visualization: Using MR technology and environmental site data, you can create highly detailed 3D models for architects, engineers and project managers to inspect.

- Mixed reality data capture (RDC): RDC is a comprehensive approach to gathering and analyzing real-time data for better planning and problem-solving.

- Maintenance and repair: MR technology streamlines building maintenance by giving technicians a glimpse into the inner workings of a system, complete with real-time updates on structural soundness and decay. It can also help newer technicians by providing guided instructions directly in the user's line of sight.

- Employee training: Unlike a VR simulation, though, an MR training experience walks users through virtual scenarios in real-world settings. This engaging quality enables more effective training in controlled, safe environments.

Trimble's XR10 solution with HoloLens is a great specific example. The MR glasses attach to an industry-standard hard hat, thus allowing them to apply a digital overlay of highly realistic project structures to the environment using real-time job site data.

Benefits of Using Mixed Reality Data Capture Tools on Construction Projects

Incorporating MR systems equipped with advanced data analytics capabilities makes it easier for construction companies to better manage projects of all types and improve their bottom lines.

Some of the many other benefits of incorporating MR into the construction workflow include:

- Collaboration: Using MR, teams can view and interact with 3D models in real time both on and off the job site. This capability makes it easier to quickly clear up misunderstandings between stakeholders and reduce human error.

- Safety: MR training simulations are a step up from VR courses in that they allow users to practice working through situations in a more realistic environment.

- Cost savings: The ability to visualize and interact with virtual models enables you to catch and resolve costly design errors before construction begins.

- Quality: When you can resolve errors early on, you reduce the risk of flaws being present at the end of the project.

- Efficiency: Smoother collaboration and greater accuracy streamline workflows and enable workers to reach important project milestones faster.

- Reputation: You can use your MR processes as a differentiator, which can help establish your company as a forward-thinking leader in the industry.

Finding ways to apply MR in your construction workflows can help your company remain competitive even as the industry continues to evolve.

Emerging Trends and Developments

Although MR technology still has a long way to go before it sees widespread adoption in the industry, it has a bright future ahead in the midst of the accelerating digital transformation (DX).

One potential application that's being developed is the use of MR for stakeholder engagement. For example, project owners could generate support for upcoming jobs by giving stakeholders virtual onsite tours of proposed structures. Stakeholders can get a more accurate idea of what structures will look like in context than they would from an AR app — and your company doesn't need to put as much work into developing a virtual experience as you would for a fully VR version.

Another promising application is remote collaboration. As the construction industry continues to globalize, MR and other XR technologies can make it possible for experts to “visit” job sites around the world without ever having to leave their offices. And greater collaboration contributes to more efficient workflows.

Learn More About MR Solutions From BuildingPoint Southeast

Mixed reality is a revolutionary technology for the construction industry. If you're looking for MR data capture solutions, BuildingPoint Southeast has the equipment you need.

Mixed reality is a revolutionary technology for the construction industry. If you're looking for MR data capture solutions, BuildingPoint Southeast has the equipment you need.

At BuildingPoint Southeast, our goal is to help construction professionals cut costs by streamlining project processes in ways that save you valuable time and effort. We carry industry-leading MR and AR solutions from Trimble, whose user-friendly HoloLink system is easy to incorporate into your day-to-day operations.

Browse our site for more information on our MR and AR solutions, or contact us today to request a free quote. A member of our team will be there to help you find what you need.